Autogenous Grinding Mill Process Iron Ore

Process of humid grinding mill for gold ore Gulin Machinery. Process of humid grinding mill for gold ore. Cost Of Grinding By Wet Vs Dry In Iron Ore semiautogenous and ball mills

WhatsApp)

WhatsApp)

Process of humid grinding mill for gold ore Gulin Machinery. Process of humid grinding mill for gold ore. Cost Of Grinding By Wet Vs Dry In Iron Ore semiautogenous and ball mills

Tube mill: Inside the cylinder, there are some grinding media. Under the friction force and centrifugal force, the media and materials feed into the cylinder are lifted to a certain height with the cylinder rotating around the horizontal axis.

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

influences the grinding efficiency. In iron ore, for instance, a variation of 2 to 3% solid content in the slurry could lead to a difference up to 10% on the energy (kWh/T) for a similar grind. Optimization of mill performance by using online ball and pulp measurements J o u r n a l P a p e r

,Gold Ore Grinding Ball Mill Machines. High Quality Ball Mill For Sale Gold Ore Mining Ball mill grinding equipment ceramic ball mill manufacturer supplier in china offering high quality ball mill for sale gold ore mining machinery ball mill qt415 hydraulic automatic concrete block making machine production line ly410 automatic mud clay soil .

Autogenous Mills operate, mechanically, similar to the ball mill. They differ in the media they use to break or grind the ore. Autogenous Mills use large particles of ore instead of steel or other balls for grinding media. Autogenous mills use large pieces of ore as grinding media.

Ball Mill: Iron Ore Processing Equipment, Star Trace offers turnkey solutions for Iron ore processing plants. We are one of the leading project suppliers for coal plants and we work closely with our customers to fulfill their specific needs.

Autogenous Grinding Iron Ore Grinding Mill China. Autogeneous Grinding Of Iron Ore. 22 Dec 2013 This page is provide professional autogenous grinding mill process iron ore information for you, we have livechat to answer you autogenous .

An autogenous (AG) mill is a grinding mill used in the minerals processing industry. It is shaped like a huge drum on its side and spins rapidly to carry ore to the top using centrifugal force. Gravity assists in smashing ore against other ore to pulverise rock to a size small enough to seperate minerals from gange.

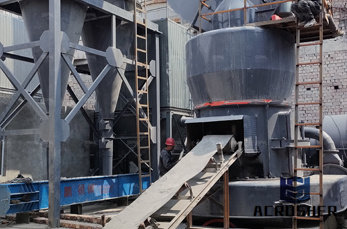

Photo of Autogenous Mill at a copper mine. Autogenous Mills operate, mechanically, similar to the ball mill. They differ in the media they use to break or grind the ore. Autogenous Mills use large particles of ore instead of steel or other balls for grinding media. Autogenous mills use large pieces of ore

xA Venezuela hard, lowgrade ironore (hematite) with a standard 74microns Bond work index of (metric) Batch testing, process simulation, and a pilot plant were conducted on a magnetic taconite ironore in 2005. Compared with SAG mill grinding, autogenous grinding using feed prepared to include coarse, competent rock and

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

This is particularly true for some of the secondary grinding (primary ball mills) of magnetic iron ores. In magnetic iron ore grinding, the silica levels are continually being decreased from crushing to rod milling to ball milling by intermediate concentration steps. Subsequently, the wear environment becomes progressively less abrasive.

Correlations for the Grindability of the Ball Mill As a Measure of Its Performance By A. Soo* and G. K. Roy Chemical Engineering Department, National Institute of Technology, Rourkela769008, India Abstract Ball mill is vital equipment in industries viz. mineral dressing, ore processing, fertilizers,

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary

Iron ore grinding is completed in the ball mill, so the Iron ore ball mill is the main place for ore materials. Just like other ball mills, the Iron ore ball mill is mainly composed by a feeding part, an exhaust end, a rotation, and transmission part(a reduction box, an electrical machine, an electronic control, and pinion drive gear) and other parts.

offers 3,151 iron ore mine ball mill products. About 55% of these are Mine Mill, 0% are Grinding Equipment. A wide variety of iron ore mine ball mill options are available to you, such as local service location, applicable industries, and warranty.

The third type of mill that I mentioned was an AUTOGENOUS MILL, this type of mill uses a completely different type of grinding media; the rock itself In conventional milling, the ore is crushed to, plus or minus, 3/8 of an inch, before it is put into a mill for grinding. In a autogenous mill the ore is fed directly into the mill from either the primary crusher or the mine itself. The size of

WhatsApp)

WhatsApp)