Extracting iron and copper Obtaining and using metals

An ore. is a rock that contains enough of a metal or a metal compound to make extracting the metal worthwhile: lowgrade ores contain a small percentage of the metal or its compound highgrade

WhatsApp)

WhatsApp)

An ore. is a rock that contains enough of a metal or a metal compound to make extracting the metal worthwhile: lowgrade ores contain a small percentage of the metal or its compound highgrade

Dec 07, 2012#0183;#32;Magnesium is extracted from its ores by the English chemist Humphry Davy found a way to extract pure magnesium metal from its an alloy of magnesium and extraction of magnesium from its ore | Solution for ore mining. How do you extract magnesium from its ore, and how expensive is it problems caused by alloying magnesium.

Manganese processing, preparation of the ore for use in various products. Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 #176;C (2,271 #176;F). Ordinarily too brittle to be of structural value itself, it is an essential agent in steelmaking, in which it removes impurities such

Jun 22, 2011#183; The three method generally used to extract metals from ores are dependent on their reactivity. The first method is electrolysis, which is used for metals like aluminum and magnesium that have a high reactivity. The second is extraction by reaction with either carbon or carbon monoxide, Inquire Now; Ways to Separate Metal From

Sep 21, 2013#0183;#32;The lab is working on a million, threeyear project to develop an extraction method which would remove naturallyoccurring magnesium from

Jan 02, 2012#0183;#32;With the depleting reserves of highgrade iron ore in the world, froth flotation has become increasingly important to process intermediate and lowgrade iron ore in an attempt to meet the rapidly growing demand on the international market. In over half a centurys practice in the iron ore industry, froth flotation has been established as an efficient method to remove impurities from iron ore.

EXTRACTION OF IRON EXTRACTION OF IRON FROM HAEMATITEDETAILS OF EXTRACTION : The process of the extraction of iron is carried out by the following steps: Concen

Jun 03, 2019#0183;#32;EcoMag says hydrated magnesium carbonate is a highpurity, highvalue magnesium product that currently fetches circa 1,250/tonne. Australian company to extract magnesium from

Iron Ore Concentrates Reduction. 16 May 2018 . Since the thermodynamics of iron ore reduction in a hot CO and H2 . Thus, dropping the iron ore size by a factor of a thousand decreases the . Mondu Akura started Using conventional approach of leaching to extract. Get Price Solvent Extraction of Iron

Dec 14, 2020#0183;#32;In an exciting move forward for the mining industry, Brisbanebased Cooperative Research Centre for Optimising Resource Extraction (CRC ORE) has announced that Hatch has been awarded an exclusive license to commercialize Grade Engineering#174; Consulting Services. Developed by CRC ORE, the innovative suite of Australiandeveloped mining technologies is set to be taken

MINING AND CONCENTRATING : Both dolomite and magnesite are hauled out and concerted by conservative methods. Carnallite is hauled out as ore or alienated from other salt amalgams that are brought to the exterior by solution mining. Naturally happening magnesium including brines are determined in large ponds by solar desertion.

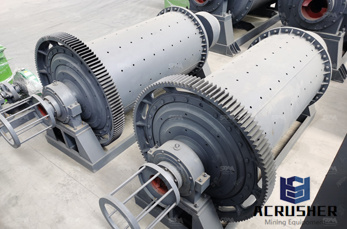

About Us. Xinhai concentrates on providing the Turnkey Solution for Mineral Processing Plant, that is research and design complete equipment manufacturing and procurement commissioning and delivery mine management mine operationquot;

The increasing demand of iron ore at home and abroad further stimulates the development of the benefication of iron ore. As one of the leading enterprises in domestic mineral processing industry, Xinhai has been dedicated commitment to the research and development of iron extraction process and equipment for more than 20 years.

Beryllium is mainly extracted in the United States, with smaller quantities coming from China, Africa, and South America. The extraction process uses leaching of the ore in sulfuric acid to produce a sulfate, which undergoes solvent extraction to remove impurity elements.

Iron ore is the unrefined substance utilized to formulate pig iron, which is one of the most important untreated materials to compose steel. 98% of the hauled out iron ore is used to produce steel. Iron ores are rocks and mineral deposits from which clanging iron can be reasonably extracted

The iron ore extracted in the deposits, mostly by blasting, is initially very coarse and unwieldy, which gives this untreated rock the name coarse ore. After the coarse ore has been extracted, it is crushed directly at the deposits with the aid of cone crushers or jaw crushers to

antimony mine extraction of magnesium from iron ore new; antimony mine extraction of magnesium from iron ore new. Efficient Thickener. Efficient Thickener. Hydraulic Motor Driving Center Thickener. High Frequency Dewatering Screen. High Frequency Dewatering Screen. Submerged Spiral Classifier.

Magnesium (Mg) is a silvery white metal that is similar in appearance to aluminum but weighs onethird less. With a density of only grams per cubic centimetre, it is the lightest structural metal known. It has a hexagonal closepacked (hcp) crystalline structure, so that, like most metals of this structure, it lacks ductility when worked at lower temperatures.

It is said that extraction of the precious iron from the mine would take almost 180 years. 2 Sia Dara Iron mine: After Hajigak, Sia Daramine is said to be the second largest mine of iron ore in the country. It is located 22 kilometres from the provincial capital in Yakawlang district.

extraction of iron ore from river sand. Efficient Thickener. Efficient Thickener. Hydraulic Motor Driving Center Thickener. Hydraulic Motor Driving Center Thickener Agitation Tank For Chemical Reagent. High Frequency Dewatering Screen. High Frequency Dewatering Screen. Submerged Spiral Classifier. Submerged Spiral Classifier. Concentrating

WhatsApp)

WhatsApp)