Cement Manufacturing Process: What is Cement made of.

Most important raw materials (what is cement made of) required in the manufacture of Portland Cement are: Limestone, Clay, Gypsum, Fuel, and Water (in wet method). 1.

WhatsApp)

WhatsApp)

Most important raw materials (what is cement made of) required in the manufacture of Portland Cement are: Limestone, Clay, Gypsum, Fuel, and Water (in wet method). 1.

#0183;#32;Lime or calcium oxide is the most important ingredient of cement. The cement contains 60 to 67% of lime in it. It is obtained from limestone, chalk, shale etc. Adequate quantity of lime in cement is helpful to form the silicates and aluminates of calcium.

Functions of Cement Ingredients. The main features of these cement ingredients along with their functions and usefulness or harmfulness are given below: Lime: Lime is calcium oxide or calcium hydroxide. The presence of lime in a sufficient quantity is required to

Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and nonspecialty was developed from other types of hydraulic lime in England in the early 19th century by Joseph Aspdin, and usually originates from is a fine powder, produced by heating limestone and clay minerals in a kiln to form clinker

#0183;#32;Cement: Cement is binding material in the cement concrete. This concrete is used for different engineering works where strength and durability are of Prime importance. Functions of cement. It fills up voids existing in the fine aggregate and makes the concrete impermeable. It provides strength to concrete on setting and hardening.

Cement manufacturing process Table (1): Raw ingredients used to provide each of the main cement elements. Table (2): Chemical and physical properties of the studied areas.

Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients. Common materials used to manufacture cement include limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore.

Manufacturing Portland Cement. The basic ingredients of both the dry and wet processes are the same. By mass, lime and silica make up approximately 85% of portland cement. The materials that are commonly used are limestone, shells, chalk, shale, clay, slate, silica sand, and iron ore.

Cement Manufacturing Process Npc. Cement Manufacturing Process Cement is the basic ingredient of construction and the most widely used construction material It is a very critical ingredient because only cement has the ability of enhancing viscosity of concrete which in returns provides the better locking of sand and gravels together in a

#0183;#32;Cement Cement The major cements: composition and properties: Portland cement is made up of four main compounds: tricalcium silicate (3CaO #183; SiO2), dicalcium silicate (2CaO #183; SiO2), tricalcium aluminate (3CaO #183; Al2O3), and a tetracalcium aluminoferrite (4CaO #183; Al2O3Fe2O3). In an abbreviated notation differing from the normal atomic symbols, these compounds are designated as

We were discussing Basics of cement and its various types in our previous posts. Today we are going to start here other one very important discussion raw materials for producing the cement. We will understand the various terminologies and engineering concepts used in cement

#0183;#32;Some of the main ingredients used to make cement include limestone, clay, shale, iron, and sand. Different manufacturing techniques will use either wet or dry grinding, but each cement manufacturing process will culminate in heating and fine grinding

#0183;#32;Portland cement is made up of four main compounds: tricalcium silicate (3CaO #183; SiO 2), dicalcium silicate (2CaO #183; SiO 2), tricalcium aluminate (3CaO #183; Al 2 O 3), and a tetracalcium aluminoferrite (4CaO #183; Al 2 O 3 Fe 2 O 3).

The cement used is ordinary Portland cement. The water required is the normal potable water. The greater the proportion of coarse aggregate, the greater will be the strength of the quantity of cement used. Mixing of ingredients: The blending of It results in the saving of precious agricultural land which is used for manufacturing bricks.

We first discuss cement production and special nomenclature used by cement industrialists in expressing the composition of their cement products. We reveal different types of cement products, their compositions, properties, and typical uses. Wherever possible, we tend to give reasons as to why a particular cement type is more suitable for a given purpose than other types.

29/10/2020 The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine of the main ingredients used to make cement include limestone, clay, shale, iron, and manufacturing techniques will use either wet or dry

Cement Manufacturing Process | Phases | Flow Chart | Cement

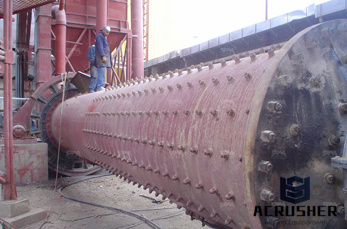

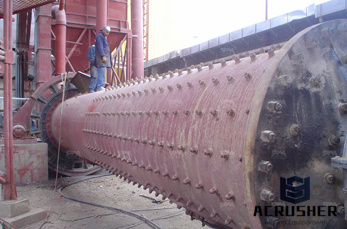

Cement Manufacturing Process 1 Extraction. Materials are extracted / quarried / recovered and transported to the cement plant. 2 Crushing and milling. The raw materials, limestone, shale, silica and iron oxice are crushed and milled into fine powders. 3 Mixing and preheating.

WhatsApp)

WhatsApp)