(PDF) Analysis of ball mill grinding operation using mill

The process of grinding cement clinker with a complete filling of gaps and performance of grinding circuits using ball mills, Applications of a new modelbased method of ball mill

WhatsApp)

WhatsApp)

The process of grinding cement clinker with a complete filling of gaps and performance of grinding circuits using ball mills, Applications of a new modelbased method of ball mill

using grinding media. Ball mills are basically a horizon tal rotating cylinder Four paramet ers are required in the displa cement For large mill, the method based on forced vibration

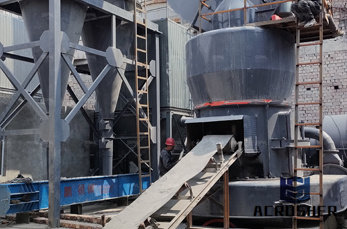

Grinding Method Using A In Cement Ball Mill Vertical Roller Mill Grinding Method Using A In Cement Ball Mill. 202064Used in cement grinding production grinding parts of its various forms there is a cylinder cone type ball type etc. and roller surface is also flat curved convex round noodles.

Artificial Neural Network Modeling of Ball Mill Grinding Process Artificial Neural Network Modeling of Ball Mill Grinding Process, Veerendra Singh, the particle size distribution of ball mill product using grinding data available for the performance of grinding circuit in mineral, metal and cement industry.

The grinding effect is thus achieved by pressure and shear forces between grinding bodies and cement, which forces are generated by said agitator, which normally rotates with about 80 and which emits a high effect per unit volume of the mill, usually in the order of at least 10 times the effect consumed per mill unit volume at a conventional ball mill.

Recommended Grinding Method Using A In Cement Ball Mill. Optimization of Cement Grinding Operation in . #183; Optimization of Cement Grinding Operation in Ball Mills. Contact Us #187; . Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with ball mills.

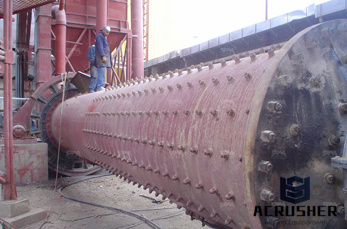

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds.

Cement Mill,Cement Clinker Grinding Plant. Working Principle of Cement Mill. Cement mill is a simplified level, out of the hollow shaft and grinding materials and other components, simplified for the long cylinder, cylinder equipped with a grinding, cylinder of steel plate, with steel liner and simplified fixed, grinding media generally steel ball, according to different tube diameters

Ball Mill Design/Power Calculation. Ball Mill Grinding Capacity Calculator Ball Mill Motor/Power Sizing Calculation Ball Mill Design/Sizing Calculator The power required to grind a material from a given feed size to a given product size can be estimated by using the following equation where W = power consumption expressed in kWh/short to (HPhr/short ton = kWh/short ton) Wi

5 Ways To Improve Grinding Efficiency Of Ball Mills News

Industrial ball mills made available by us are heavy sheet fabricated using qualityapproved mild steel stainless steel These ball mills are used to grind materials into extremely fine powder Our ball mills are perfect for cement plants Three types of ball Mills we re manufacturing 1 Raw materials mill 2 Cement Clinker mill 3We are a professional mining machinery manufacturer, the main

Grinding Media Charge Calculation In Cement Ball Mills. Mill Steel Charge Volume Calculation . We can calculate the steel charge volume of a ball or rod mill and express it as the of the volume within the liners that is filled with grinding media while the mill is stopped the charge volume can be gotten by measuring the diameter inside the liners and the distance from the top of the charge to

Please find below two calculators for sizing mills using the Bond and Rowland methods: Ball mill sizing: Calculator for ball mill(s) in a single stage circuit. Rod ball mill sizing: Calculator for rod mill(s) as first stage of the circuit and ball mill(s) as second stage of the circuit.

Several types of ball mills exist. They differ to an extent in their operating principle. They also differ in their maximum capacity of the milling vessel, ranging from liters for planetary ball mills, mixer mills, or vibration ball mills to several 100 liters for horizontal rolling ball mills.

#0183;#32;Several factors affect the efficiency of a ball mill for cement grinding. In this article, we shall be looking at some of these factors that have been proven to influence grinding efficiency: Mill Geometry And Speed. According to Bond (1954), the grinding efficiency of a mill depends on the ball mill diameter, size of the media and mill speed.

In the article attention is paid to improving the efficiency of production of fine powders, in particular Portland cement clinker. The questions of Portland cement clinker grinding in closed circuit ball mills. Noted that the main task of modeling the grinding process is predicting the granulometric composition of the finished product taking into account constructive and technological

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

A cement mill or finish mill in North American usage is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Ball mill Wikipedia A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing A ball mill consists of a hollow cylindrical shell rotating about its axis. and it is widely used in production lines for powders such as cement sili es. USB1 Cement clinker grinding method using

Optimization of mill performance by using online ball and pulp measurements Soon after a stop, a mill is a dangerous place to enter for the personnel tasked with taking measurements or samples. Crash stops are difficult to handle. The mill and all feed streams should be stopped simultaneously but, often, they are stopped around about the same time.

WhatsApp)

WhatsApp)